NanoBiz Korea

나노비즈코리아

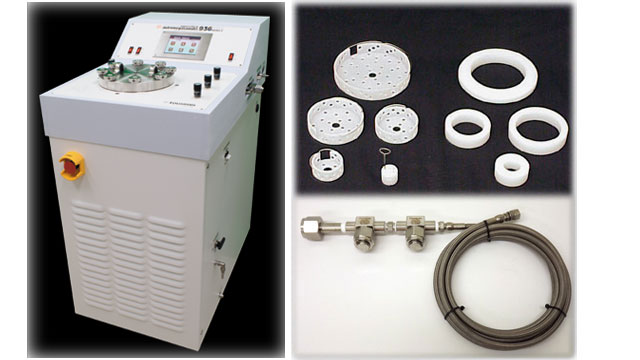

The New Supercritical Automegasamdri®-936 System was developed by our in-house design team whose goal was to listen to and incorporate your needs into our next generation.

The classic features you have come to expect for decades that enable smooth operation, precise control and reproducibility are again evident in our most current design.

제품설명

• Process up to Five 6" (150mm) Wafers per Process Run

• Touchscreen Programmable Interface

• First Time Ever...Previous Run Data Review

• Integrated Chiller Loop Decreases LCO2 Consumption

• Easy Facilitation with Small Foot Print Design

tousimis catalog# 8788B

FEATURES

> A dedicated initial Slow Fill into the process chamber allows ideal fluid dynamics preserving the most sensitive micro devices.

> Maintenance made easy via accessible components including the external Post-Purge-Filter assembly.

> Patent Pending "Vortex Swirl": Non-mechanical stirring chamber allowing for fluid dynamic exchange without the need for particle generating friction causing devices.

> Extremely Efficient integrated Closed Cooling Loop dropping chamber temperature quickly for shorter process run times.

> The internal SOTER(tm) condenser quietly captures and separates CO2 exhaust and waste alcohols.

> Our original Chamber Inserts enable chamber I.D. variance of chamber I.D. maximizing efficiency in LCO2 consumption, process time, and providing multiple size wafer process capability!

> Process chamber LCO2 filtration down to 0.08µm with 99.999%+ particle retention.

> Processes up to five 6" (150mm) wafers each run. Included are the following HF Compatible Wafer Holders: 6" (150mm), 4" (100mm), 3" (75mm), 2" (50mm) and 10mm Die Holders.

> Chamber Illumination via viewing window facilitates chamber status visualization.

> Automatic process with factory default recipe or the ability to customize your own!

> All internal surfaces are inert to CO2 and ultrapure alcohols.

> Repeatable operating parameters insuring "reproducibility" of results.

> Safety operation features integrated into both temperature and pressure automatic regulation.

> All electronic components meet CE, UL and/or U.S. Military Specifications.

> Clean room static-free compatible design.