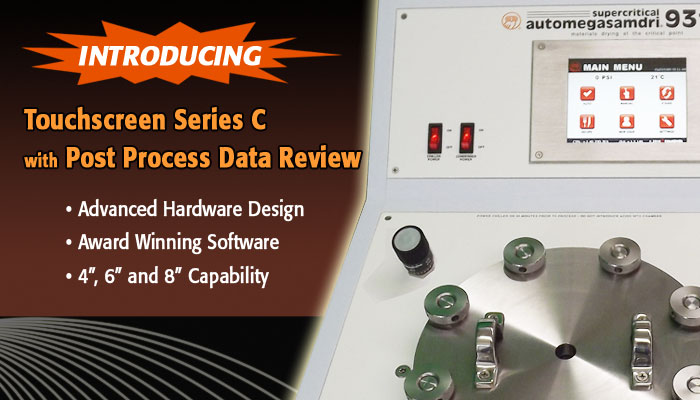

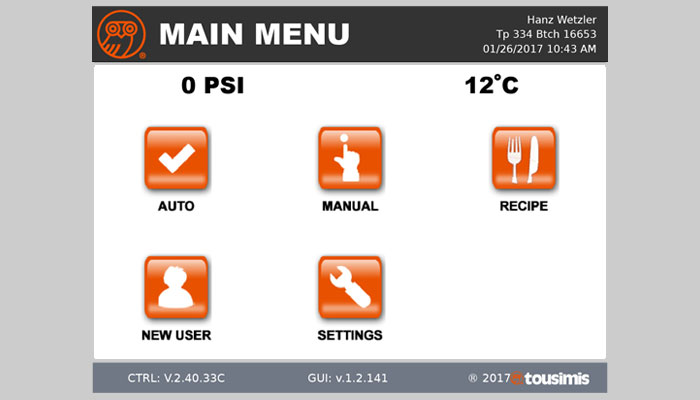

Features- > Bright LCD Touchscreen Control

- > Use Factory Default Automatic Settings or Create Custom Recipes

- > Optional "Stasis Software" (Patent Pending) for versatile sample types

- > Process up to 5 wafers per process run with each system

- > HF Compatible Wafer Holders and 10mm square holder included with each system

- > Tousimis® HF compatible Wafer Holders may be used to etch and process your wafers minimizing handling

- > Unique chamber inserts easily reduce chamber ID decreasing LCO2 consumption

- > High efficiency internal closed loop refrigeration integration

- > "Vortex Swirl" non-mechanical purge stirring (Patent Pending) eliminates moving parts for easy maintenance

- > Repeatable operating parameters insuring “reproducibility” of results

- > Static pressure control module helps insure automatic safe pressure stability

- > Internal filtration system delivers clean LCO2 into process chamber down to 0.08µm

- > New 'Slow Fill' Control for the most delicate Sample Types

- > LCO2 flow is controlled through Micro Metering Valves with Vernier handles for precise flow control and easy position setting readjustment

- > Chamber illumination with view port facilitates chamber status visualization

- > All internal surfaces are inert to CO2, Acetone and Ultrapure Alcohols

- > Cleanroom static-free compatible design

- > External mounted Post Purge Filter Assembly for EZ preventive maintenance maintenance

- > The patented internal SOTER™ Condenser quietly captures and separates CO2 exhaust and waste alcohols

- > All electronic components meet CE, UL and/or U.S. Military Specification

- > Cabinet: 19.8" (50.3cm) Width x 31.7" (80.6cm) Depth x 44.5" (113.0cm) Height

- > System Set-Up Area Footprint: 27" (68.6cm) Width x 38" (96.5cm) Depth x 44.5" (113cm) Height

- > 120V or 220V / 50-60Hz systems available