NanoBiz Korea

나노비즈코리아

agar scientific

제품설명

Product Description

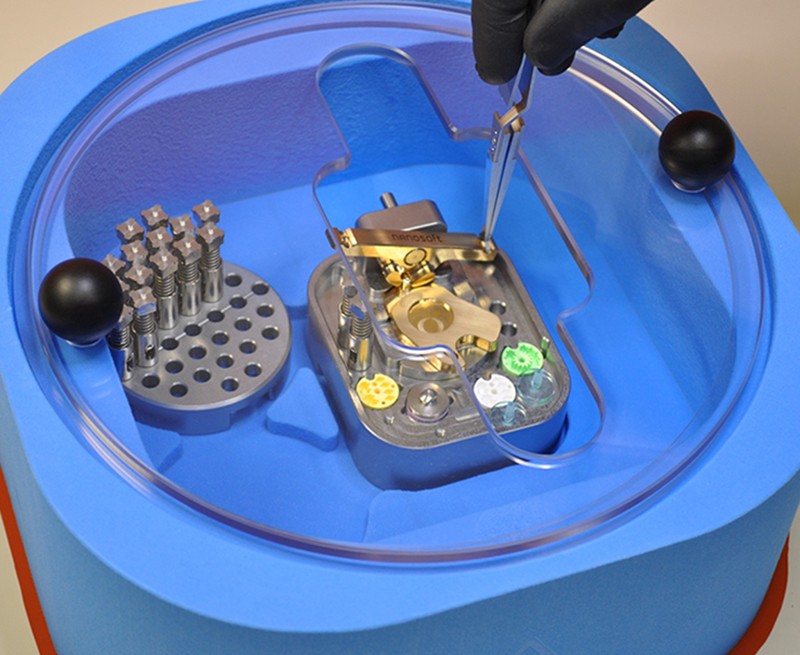

Optimised for the clipping workflow, the NanoSoft clipping station provides easy and efficient clipping of Cryo-EM grids for Thermo Fisher autoloader-based microscopes.

High-quality foam dewar (AGK110 & AGK111) integrates grid box storage puck access directly adjacent to the clipping station, increasing ease of use and reducing the potential for contamination transferring grid boxes from pucks in other stations.

Key features:

Foam dewar - manufactured form a high-quality, durable, closed-cell polyethylene

Clipping Hub - newly designed to make workflow easier

Lid - provides optimal balance between usability and separation of the clipping space from the ambient environment

Silicone mat - reduces station movement when rotating lid

Compatible with Cryo Grid Box Storage Pucks - grid boxes can be accessed without needing to transfer them through the ambient environment from another dewar

Technical Data

Clipping Station

The clipping station is housed in a high-quality, closed-cell polyethylene foam. The foam is highly durable and cools down and warms up/dries off quickly.

The inside of the foam dewar is designed to match the intricacies of the workflow; there are 3 cutout positions in the foam, each of which holds a component firmly in place to avoid movement during use. One cutout holds the clipping hub (the part used for clipping). The other two cutouts are the appropriate size to hold storage pucks. This allows the user to place a storage puck directly and securely in the clipping station adjacent to the clipping hub, to ensure grid boxes can be accessed without needing to transfer them through the ambient environment from another dewar.

The station comes with a puck-sized holder for up to 33 tools that can be pre-loaded with C-Clips and placed in the holder to be cooled down while being held reliably in place. The puck and tools are in a position that is easy to access and enables seamless clipping of up to 33 samples at one time with one puck-full of tools.

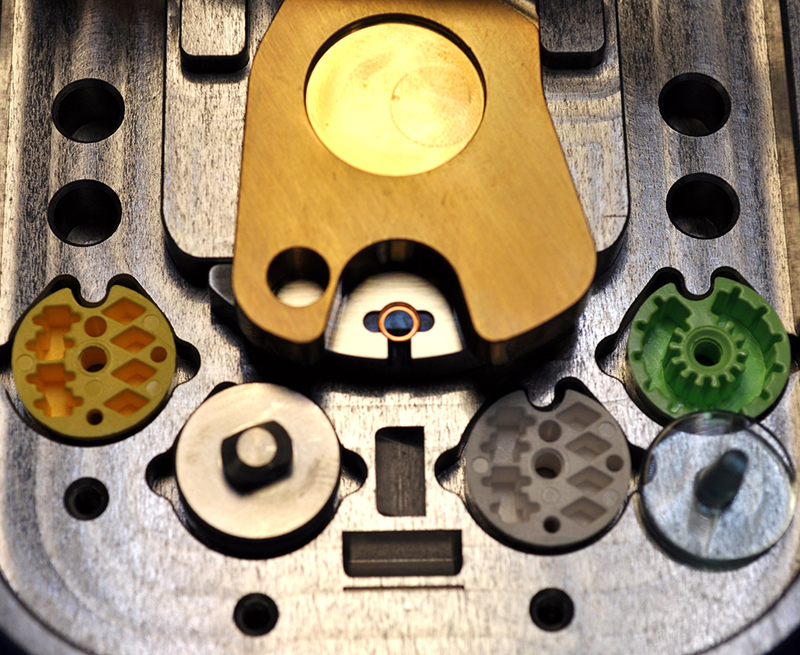

Clipping Hub

Instead of the rotating brass cylinder, which is often difficult to turn and can bend tweezers, the seesaw-like mechanism requires the user to push down on either side of the cantilever beam to move the guidance cylinder into the position for clipping or into the position where the autogrid ring is placed, or where the clipped grid can be picked up.

Once the system and clipping tools are cooled down, and a storage puck placed into its spot adjacent to the Hub, the grid box holding the grids to be clipped can be moved to a grid box pocket in the Hub for easy grid access for clipping, and replacement of the autogrid after clipping.

The Hub has 4 'on-deck' positions for clipping tools where they can quickly be accessed for rapid-fire clipping. The shallow hole where the autogrid ring is placed for clipping has a dark-coloured surface to provide better contrast and easier tracking for placement of the autogrid ring and picking up of the clipped grid with autogrid tweezers.

Grooves are machined into the Hub to enable inspection of the clipped grid to ensure that it is well clipped and to roll the notch of cryoET, and FIBSEM rings into the right orientation.

Clipping Station Lid

The lid for the station provides a balance between usability and efficient separation of the clipping space from the ambient environment. The optimally designed opening in the lid provides the ideal amount of space to access:

The cantilever

Grid box pockets in clipping hub

4 'on-deck' clipping tools

Access is available without the requirement to rotate the lid while providing protection from ambient humidity.

Knobs on the lid enable easy turning to access and transfer other grid boxes or clipping tools to the Hub, and a Lid insert can cover the entire opening so that the clipping space can be closed off from the ambient environment completely during cool down and as needed.

A silicone sheet is provided upon which the entire station can be placed to reduce station movement when rotating the lid.